This is something related to casting.

concept you must understand is about "Draft Angle".

Any part with significant depth of draw should use a cavity draft angle.In traditional molding where the core is the moving half of the mold,it is desirable for the part to ‘stick’ the core side for ejection.Material shrinkage helps with this in two ways.Shrinkage causes pressure and friction between the part and the core, and the part shrinks away from the cavity of the tool.Draft is typically added to the cavity side of the tool with ½ degree minimum.

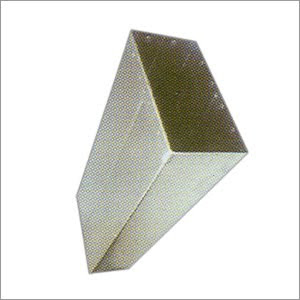

Draft also reduces abrasion and wear between the part walls and the cavity during the mold opening.The picture below helps to explain draft angles.

you will understand it in better way from animation of pattern removing from mould click the Link provided below for same

http://www.nptel.iitm.ac.in/courses/Webcourse-contents/IIT-ROORKEE/MANUFACTURING-PROCESSES/metalcasting/lecture4.htm#

No comments:

Post a Comment